Brandt Farm - Carroll, Ohio

David and Kendra Brandt purchased his grandmother’s farm in 1971 after being honorably discharged from the Marine Corps and serving in Vietnam. It was his grandmother’s grandfather’s farm before that.

The farm is located in Fairfield County, Ohio near the town of Carroll, OH. It currently consists of 736 acres of no-till row crops and cover crops. David also has a cover crop seed company and a seed-cleaning business that operate on the farm.

The operation now involves three generations of the family that are actively involved in the day-to-day operations, including his son and daughter-in-law and a grandson who became a partner in the farming operations in January 2020.

David Brandt at Home on the Farm

Transition Process:

The Early Years

David grew up on a farm, but when his Dad was killed in a tractor accident, the farm had to be sold to pay estate taxes. Just out of the Marine Corps, David started his farming career as a tenant farmer in 1969 on a farm owned by the niece of J.C. Penny, founder of the department store chain. The farm was not being used at that time and approached David about his interest in farming the property. David started with 60 Charolais cows and 80 sows in a farrow-to-finish hog operation on 550 acres. He experimented with no-till planting of crops, starting with an Allis-Chalmers no-till planter, a new John Deere 3020 tractor, a John Deere model 45 open cab combine and a 30-gallon sprayer. He became involved with Chevron Chemical by using their paraquat herbicide as a burn-down to terminate weeds prior to no-till planting his row crops.

His involvement in experimenting with no-till came as a result of a mentorship program in the late 1960’s that encouraged him to try new farming methods as a young farmer-veteran. He was paid $3000 per year by the program to implement no-till practices and to host an annual field day on his farm. His involvement in the program made David one of the first farmers in Ohio to try no-till planting and he is likely the longest term no-till farmer in Ohio. He went 100 percent no-till in 1971.

In that same year, he purchased his grandmother’s farm but continued to farm the 550 acres owned by the niece of J.C. Penney. He was on what he calls the “Southern Farm” as a tenant farmer for 17 years until the end of 1985. With the combination of the two farms, he grew his cow herd to 200 Charolais cows and 200 sows farrow-to-finish. He fed out about 8000 pigs annually in a total of nine barns. Unlike the common practice in his region, he never put his cows up in barns during the winter, instead wintering them out on perennial pasture and crop residue.

He grazed 20 cows and their calves on about 110 acres of perennial pasture and some of his row crop acreage, moving the cows every 8-10 days to a new pasture. Each pasture had about 35-40 days of rest between grazing events.

His goal on the cattle was to achieve a 95 percent-plus calving rate and to feed out the majority of his annual calf crop in his on-farm feedlot. He achieved both goals and was able to finish cattle at 13-14 months of age, weighing about 1200 lbs live weight at harvest. His weaning weights averaged between 550 and 650 pounds. He fed a combination of ground-ear corn (grinding of the cob and grain together) and alfalfa. He kept all his corn harvest as intact ears in a corn crib and shoveled corn from the crib to the grinder on a daily basis. His fat cattle were sold on the rail to a packer in Columbus, OH. His cattle averaged 82 percent USDA Choice and Prime in the carcass.

He implemented a cash crop rotation that consisted of one-third of his row crop acres in corn, one-third in soybeans, and one-third in wheat. On the wheat acres, David sowed clover and timothy after the wheat harvest for additional pasture grazing between cash crops and to make hay. He also grazed all of his “fodder” ground, or row crop acres that had been harvested utilizing the leftover residue as fodder.

During this time, he started experimenting with cover crops, using monoculture plantings of either hairy vetch or cereal rye. What he planted was dependent on when he was able to remove the corn crop at harvest. He would allow the cover crop to grow to about 8-10 inches in height and turn in the cows and calves. He would also follow his wheat crop with a combination of annual ryegrass, orchard grass and clover for cool season grazing before the next cash crop.

Because the farm had a wet footprint with low soil aggregate and poor water infiltration rates, David installed tile every 100 feet across the farm.

Aerial View of the Brandt “Home Farm” in 2022

Big Change

David and his wife Kendra moved to the farm he purchased from his Grandmother in 1985. His mother-in-law had suffered a stroke, requiring Kendra and he to be near in order to take care of her. The owner of the tenant farm did not want David to move and insisted that he stay put. David and Kendra refused and moved to their purchased farm. At that time David owned 50 percent of all the livestock and all of the equipment. He had built his cow herd to 300 cows and had 300 sows. The sale of all the cattle and hogs allowed the two to pay off their owned farm and to build a house.

This started a new chapter in David’s life that did not include livestock—just row crops and cover crops on his deeded 736 acres. At that time, he did not have the capital to re-invest in livestock and has not had livestock since that time. He stated that if he knew then what he does now about the benefits of properly grazed livestock, he would have done whatever was needed to re-purchase cows and use them for their soil building advantages.

Right: David Brandt Explaining No-Till

Planting into Cover Crops

The Path to the Present

David was always doing things a little different than his farming neighbors, but a chance encounter in 1997 with an early cover crop advocate by the name of Steve Groff altered his thinking even more. Steve inspired David to try a greater array of cover crop species and options. At this point, David started collecting information on how these cover crops species performed on his farm. He purchased a White no-till planter and planted tillage radishes and peas as a two-way cover crop. He paid careful attention to plant performance and nodule development on the legumes. He would actually pick off the individual nodules and weigh them. The tillage radishes were added as a possible way to break up old plow layers.

He also conducted trials with various levels of nitrogen fertilizer, after the starter fertilizer was applied. He would examine nitrogen applications from zero (0) pounds per acre to 200 pounds per acre in order to determine how much nitrogen fixation his cover crop legumes were providing in replacement of the applied nitrogen.

One very interesting thing that he noticed was that radishes planted as a companion crop to winter peas would result in 13 percent more root nodulation and nitrogen fixation than when multiple pea species were planted together. He noted that the radish roots would grow intertwined with the pea roots and this seemed to produce significantly better root nodulation on the legumes. He also observed that the tillage radishes would grow to 3-4 inches in diameter and more than a foot deep.

David had been told that as the radishes rotted they would produce potentially harmful impacts on the soil and tie up nutrients. However, David noted that there were positive effects that seemed to stimulate greater mineral cycling in the soil. He later found out that the radishes were producing sugars that “fed” the soil microbes and enhanced nutrient cycling.

Next Encounter

In 2002 David read an article about Gabe Brown and what Gabe was doing with cover crops in North Dakota. He decided to go hear Gabe speak in nearby Kentucky. David talked at length with Gabe after the presentation but did not immediately make any changes. However, the next summer Gabe attended a field day at David’s farm. At that field day event, Gabe asked David why he wasn’t using more diversity in his cover crop mixes. That challenge prompted David to give it a try and he started experimenting with 6-10 species mixes as he became more aggressive in his approach.

Rolling Down and Planting into Cover Crops at Brandt Farms

David started seeking mixes of various plants that would be compatible with each other, produce deeper roots, greater root mass, and break up old soil compaction layers. He also started sending soil samples to Rick Haney, Ph.D. of USDA’s Agricultural Research Service, developer of the Haney Soil Test. These tests allowed David to gain a better understanding of which cover crop mixes were stimulating soil microbes to release a greater array of macro- and micro-elements to feed plants.

David believes the significant resource and production improvements made during the past couple of decades have mostly peaked on the home farm. However, he believes incremental improvements can still be made beyond 2022 by experimenting with and learning how to best refine the mixes, legume/grass combinations and varieties of cover crops he uses in his farming operations.

Key Points of Progress:

- In 1971 the soil organic matter on David’s newly purchased farm was 0.75% with phosphorus levels as measured by standard soil tests of 38 ppm and potassium levels of 90m ppm. The soil pH was very low at 4.2, prompting David to apply 2 tons of lime per acre.

- By 2022, the soil organic matter averaged 8.7% on the home farm. In contrast, the soil organic matter on an adjacent farm he purchased 2016 was 1%. Under David’s soil health management, the soil organic matter on that farm has increased to 5%.

- Phosphorus levels have increased to 75-80 ppm and potassium levels to 300-500 ppm. The soil pH is now 6.9 with no lime applied since 1971.

- David’s ability to infiltrate water has increased from less than 25,000 gallon per acre to more than 175,000 gallons of water per acre.

- The “A” profile in his soil is now 47 inches deep compared to less than 6 inches in 1971 and acts like a giant sponge for water infiltration and retention.

- From 1971 through 1989 David used an average of 150-250 pounds of nitrogen fertilizer per acre to grow his corn crops. After adding peas and radishes as a cover crop mix, he cut his nitrogen needs in half and was able to get it down to 90 pounds per acre by 2022.

- When he added multiple species and became more aggressive with his cover crop mixes, he was able to achieve an additional drop in applied fertility. His starter fertilizer is now just 2 lbs of N, 4 lbs of P, and 5 lbs of K. His corn crop now only requires 20-30 lbs of N throughout the entire growing season. He requires no fertility for his soybeans, relying on fertility gained solely through his cover crops. He uses only 40 lbs of 10 N – 10 P – 10 K for his small grains.

- Thirteen years ago, David stopped using any fungicides and insecticides. This occurred at a time when fungicide and insecticide use has increased significantly with the average commodity farmer.

- Seven years ago, he stopped using any seed treatment, including

- After increasing by an average of 5% annually from 2015-2020, his cash crop yields have been holding consistent, and he is still using far less fertilizer, no fungicides, insecticides or seed treatment.

- He does not carry any crop insurance since his yields are always above the county average. That has saved him significant cost and allowed for greater net margins per acre.

- His corn averages 185 bushels per acre with up to 220 bu/ac in higher precipitation years. His soybeans average between 65 and 82 bu/ac, while his wheat averages between 100 and 110 bu/ac. This is all on non-irrigated land (dryland production).

- Over the last seven years his actual direct costs per acre for corn production have been $202/ac. The average for farmers in his region is $450 - $475/ac. With same amount of profit.

- His soybean direct costs of production have been $175/ac while the average for farmers in his region is $400/ac.

- David’s direct costs of production include his cost for the cover crop seed.

- His input costs have decreased 72-78% from 2009 to 2022.

- David now uses all non-GM seed and harvests his own seed for replanting each year. He invested in a seed cleaning business and can now produce his seed for about $11/ac compared to buying it for $50/ac.

- He now uses only 2.4 gallons/acre of diesel fuel annually. The average farmer in his region is using 25-30 gallons of fuel per acre.

- In working with other farmers to reduce their fuel cost, he has been able to achieve 9-13% fuel savings on their farms in the first two years by simply using cover crops in their rotations. Fuel usage during harvest with the combines has decreased 9% in Year 1 in fields that were cover cropped.

- David and his family have now hosted an annual field day on their farm for 40-straight years. Attendance has been as high as 500 people, with people from all over North America and other parts of the world represented. They now limit attendance to 200 people and fill the event each year.

- In 2021, Brandt Farms began milling and marketing heritage/open pollinated varieties of wheat and corn. These older varieties offer consumers grains with more flavor and protein and are sold directly to customers through (regengrain.com), a website dedicated specifically to the marketing and sales of those products.

- With sales and product enterprises expanding, David’s grandson was brought on in 2022 as the cover crop mixer and product packaging and order fulfillment manager. David expects further staff support for the farm’s various business and product enterprises will be necessary as sales expand in the years ahead.

- In 2022, Brandt Farms began leasing cover crop land for sheep grazing. The lease provides an additional revenue stream for the farm and, through well-managed “mob grazing,” the 247-head of sheep provide additional soil health benefits for land.

Interesting Projects:

In 2019, David had 96 faculty from Ohio State University visit his farm to see what he is doing. The visitors included both the president and the chancellor of the university. Interestingly, only three of the faculty visiting the Brandt Farm were agriculture faculty. Instead, faculty from the disciplines of science (biology, botany, zoology, ecology), English, history, mathematics and economics came to see what David was doing to regenerate soils and ecosystems.

In 2019, David also had delegations from the Ukraine and from China visit his farm. This included ambassadors from each country, and a number of their most prominent agronomists.

Participants at a 2019 Soil Health Academy at Brandt Farms

David is now working closely with Dr. Isman from the Piketon Research Station of Ohio State University to study crop nutrient density and correlating soil health parameters. Together, they are examining various cover crop seed plots to determine their ability to cycle nutrients and collect nitrogen from the atmosphere for use by plants. They are first looking at these effects in small plots and then transferring to farm scale field production. Interestingly, Dr. Isman initially told David that multi-species cover cropping was not practical and would not provide any advantages over single species cover crops. However, after noting the advantages in the very first year of his exposure to multi-species cover crops, Dr. Isman had a change of mind and heart. He noted more root development, soil aggregation, plant biomass production and mineral cycling with the multi-species cover crops compared to the single species covers.

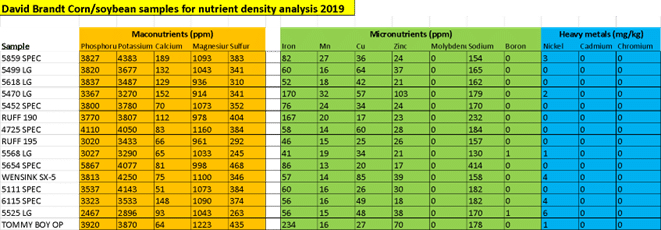

David and Dr. Isman are now also working to evaluate nutrient density and performance of various corn and soybean varieties grown in regenerative conditions without the use of fungicides, insecticides, and with significantly less fertilizer applied. This also includes their ability to perform in rolled-down cover crops at biomasses between 20,000 and 40,000 lbs. per acre. Table 1 shows results from some of those trials.

Table 1. Corn Variety Differences in Nutrient Density

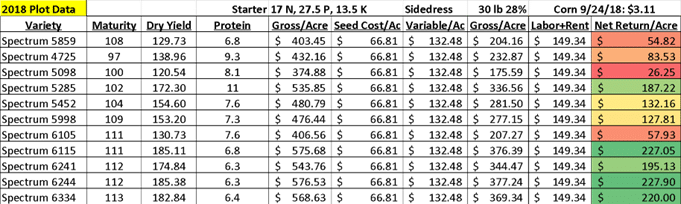

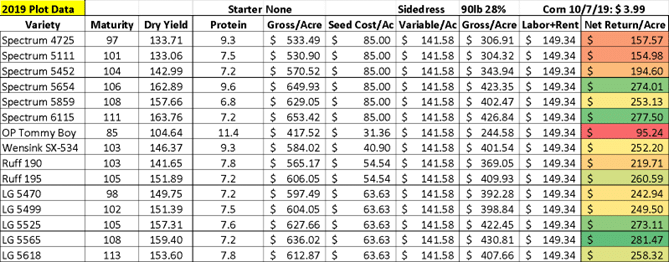

Also being evaluated are crop performance characteristics, such as date to maturity, yields, protein content (%), gross profit per acre, direct costs, and net return per acre. Table 2 presents the 2018 performance data while Table 3 presents the 2019 performance data.

Table 2. 2018 Corn Variety Performance Data in Regenerative Plots

Table 3. 2019 Corn Variety Performance Data in Regenerative Plots

What the data tells us is that crop varieties developed to perform in degraded soil conditions with a lack of cover crops and with heavy applications of synthetics and pesticides, do not necessarily perform as well when grown in regenerative soils with reduced inputs. It is important to identify varieties than thrive with the influence of cover crops, no-till practices, and enhanced soil mineral cycling that lead to reduced inputs.

In 2021, as part of the OSU plot trials, David planted seven different varieties of corn. Those varieties averaged an 8-11% protein content, providing further verification of the enhanced crop performance and quality achieved through soil health management practices.

The measured protein content for soybeans grown in the 2021 study’s plots were as follows:

- Food-grade soybeans: 44.3%

- Non-GMO soybeans in rye covers: 42.1%

- Non-GMO soybeans in corn: 42.1%

- GMO soybeans (as a control): 34.5%

It is interesting to note that David’s work has resulted in a significant change of the soil types on his farm. What started as a basic heavy clay soils when David purchased the farm in 1971 have been officially re-classified by Ohio State University soil scientists as a highly fertile silty loam soil.